Norgas SSLNG Vessel Solutions

Norgas has more than 35 years of experience in Liquefied Gas Transportation and has been designing, constructing, managing and operating Small-Scale LNG (“SSLNG”) carriers for abt. 10 years.

We have proven design for a 6,700-7,500m3 SSLNG vessel, which with its ship lines and other features makes it an industry leader in fuel efficiency. The fuel consumption of only 10 tons LNG per day at service speed of 13.5 knots is very attractive for commercial and environmental reasons being up to 30-40% less than competitive LNG designs.

We have designs for larger SSLNG vessels of up to 30,000m3 size in cooperation with partners.

For propulsion we believe that the fuel choice is clear; in the short to medium term LNG as fuel provides immediate CO2 emission reductions, more or less elimination of particle emissions as well as cost savings vs alternative fossil fuels. Longer term, Bio-LNG is a credible zero-carbon pathway with massive, unrealized potential utilizing the same infrastructure as LNG.

| Brief technical details | |

|---|---|

| Vessel size’s: | 5,000-30,000m3 |

| Cargo: | Single gas LNG or Multigas (flexible LNG vessels capable of carrying LNG, in addition to other liquefied petroleum gases) |

| Propulsion: | LNG / Dual fuel |

| Lead time: | 24-36 months inc. commissioning |

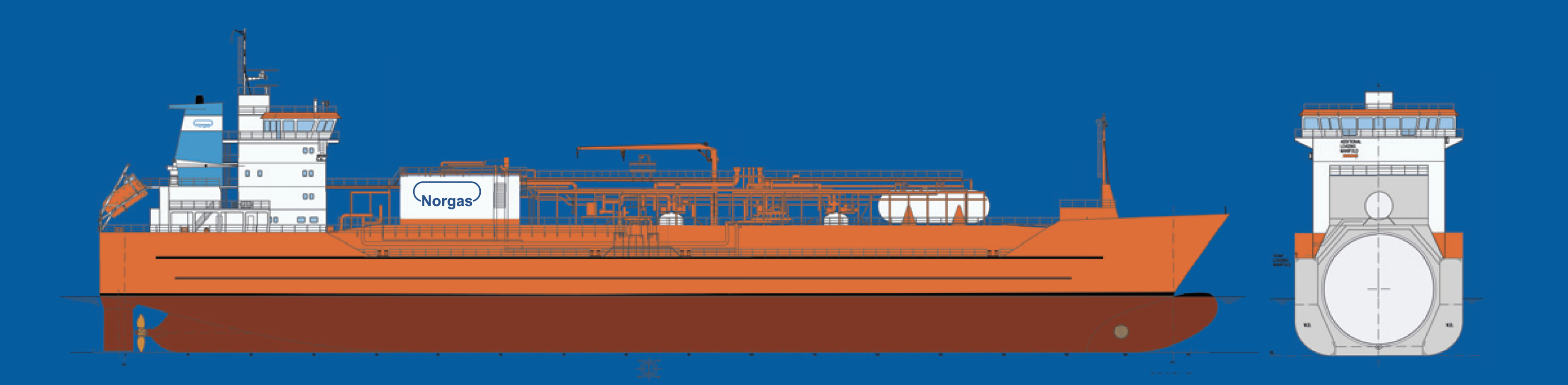

Single Gas LNG 6,700–7,500m3 SSLNG Vessel Design

| Main Characteristics | ||

|---|---|---|

| Length Overall | LOA | 119,00 m |

| Breadth (Moulded) | B | 18,6 m |

| Draught (Design) | D | 5,5 m |

| Service speed (at design draft) | Vs | 13,5 Knots |

| Range | Nm | 8,500 Nm |

| Consumption (approximate) | LNG/PD | 10 mt |

| Volume Cargo tanks (2x) | m3 | 6,700 m3 |

Multigas Vessel Designs – Building on previous success

In 2008 Norgas started the design, engineering, and construction of the 6 first Small-Scale LNG / MultiGas carriers in the world at a total cost of about USD 300 million. The vessels have a cargo capacity of 10,000 to 12,000m3.

The Norgas Multigas Carriers were designed and built as semi refrigerated gas carriers for worldwide trade. These are flexible vessels capable of carrying LNG, Ethylene, LPG and VCM. The ships were built at Taizhou Wuzhou Shipbuilding under management, coordination and supervision by Norgas. Norgas Carriers operated the ships for abt. 10 years.

The cargo plant was designed to carry two grades of gas simultaneously completely segregated, cooled or un-cooled, and capable to reliquefy LNG,LPG and petrochemical gases. The Multigas Carriers are equipped with nitrogen plant and deck tank, enabling efficient and independent purging and change of grade operations. A gas combustion unit is fitted to serve as a gas burner when gas freeing and back up for cargo tank pressure control. The loading or discharge time for a full cargo is about 9.5 hours.

In order to be able to load at large scale LNG terminals the Multigas ships are equipped with an additional elevated loading platform with a set of vapour and liquid manifolds to meet the working envelope of the LNG loading arms. They also have sets of manifolds suitable for smaller terminals.

| Main Dimensions | Tonnage | Machinery |

|---|---|---|

| Loa 137.1 m | DWT 10,600 | Main engines * 7,000 kW |

| Lpp 127.2 m | GRT 10,060 | Shaft generator 1,900 kWe |

| Breadth 19.8 m | NRT 3,020 | Auxiliary generators 3 x 910 kWe |

| Depth 11.5 m | ||

| Design Draught 6.7 m | ||

| Scantling Draught 8.3 m |

| Speed & Range | Consumption |

|---|---|

| Service Speed 16.5 knots | Main Engines (IFO 380) 27 ton/day |

| Range 12,800 nm | Auxilaries (MDO) 1.5-10 ton/day |

| Cargo System | Deck Tank | Other Tank Capacities |

|---|---|---|

| Volume Cargo Tank 1: 6000 m3 | Deck Tank Volume 110 m3 | Heavy Fule Oil Tanks 1,050 m3 |

| Volume Cargo Tank 2: 4000 m3 | Max pressure (USCG) 18 bar g | Marine Diesel & Gas Oil Tanks 175 m3 |

| Max presure (IMO/USGC) 5.2 / 3.8 bar g | Max gravity 0.65 ton/m3 | Lubrication Oils 60 m3 |

| Max gravity 0.97 ton/m3 | Min temperature -163°C | Fresh Water Tanks 180 m3 |

| Min temperature -163°C | Ballast Tanks 5,800 m3 | |

| Cargo pumps capacity 640 / 380 m3/h | ||

| Total head LPG/LNG 120/220 mlc |